Remember how blobs of liquid metal morphed into Robert Patrick’s T-1000, the ultimate killing machine in Terminator 2? North Carolina scientists say that sci-fi fantasy is now reality, as a low-voltage current can be used to create morphing electronics.

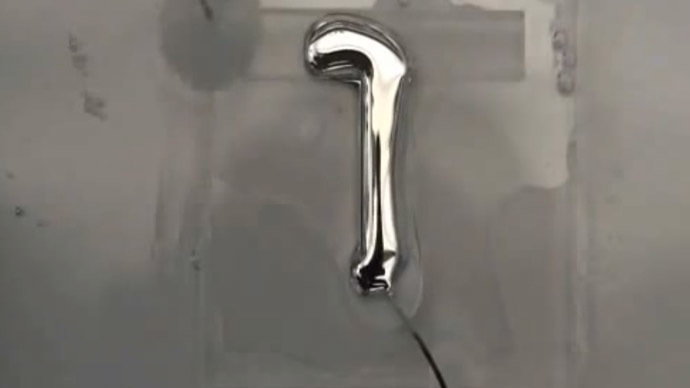

In the research by a group of scientists at North Carolina State University (NCSU), an alloy of liquid metals was forced to take shapes, driven by a low-voltage electric current. They say that getting control over the surface tension of liquid metals could evolve into morphing and self-healing electronics technology.

The scientists forced an alloy of Gallium and Indium to expand in a designed way, Gizmag reported. The research was first published in the online journal, Proceedings of the National Academy of Sciences.

Researchers chose the Gallium/Indium alloy because of its outstanding high surface tension (500 millinewtons per meter (mN/m). This tension enables a blob of such an alloy to form and hold a practically undisturbed spherical ball shape.

Gallium’s melting point is around 29 degrees Celsius, whereas Indium is becoming liquid at much higher temperature of 156 degrees Celsius. But when amalgamated, they make an alloy that melts at room temperature. A mixture of metals with disparate melting points is called a eutectic alloy.

A very small electric current of less than one volt, applied to a Gallium/Indium alloy submerged into water, resulted in significant surface tension reduction, which allowed scientists to spread and flatten the alloy in the desired way. Once the voltage is removed, the alloy reacquires its spherical shape.

Electric current also regulates the extent of the surface tension, making it possible to vary the liquidity of the alloy from the original 500 mN/m down to a mere 2 mN/m, and in any state in between.

"The resulting changes in surface tension are among the largest ever reported, which is remarkable considering it can be manipulated by less than one volt," said Dr. Michael Dickey, an associate professor of chemical and biomolecular engineering at NCSU who was the lead author of the research. "We can use this technique to control the movement of liquid metals, allowing us to change the shape of antennas and complete or break circuits. It could also be used in microfluidic channels, MEMS, or photonic and optical devices. Many materials form surface oxides, so the work could extend beyond the liquid metals studied here,” he said.

The capability to change shapes at would be highly welcome in radio electronics, as the Gallium/Indium alloy can change, for example, shapes of an antenna, making it highly tunable and capable of transforming its shape to receive or transmit a wide range of different wavelengths while operating the same component.

"If you can change the shape, you can change the function," Dickey said. "We could develop potentially better antennas for cell phones that can respond to changing conditions.”

Michael Dickey outlined other possible utilizations of the emerging technology.

In medicine "we could see embedded electronics in gloves that

a doctor or lab technician might wear, such as feedback sensors

or prosthetics, and the doctor wouldn't even know that they were

there," he told Phys-org.

Among other possible applications, he mentioned wearable devices,

such as watches.

Probably the most impressive use of operable liquid metal alloys could be robotics, he said.

"Most robots that work in factories are made out of stiff materials and aren't good interfacing with humans," he said. "Taken to the extreme, imagine an octopus with large freedom of motion that could perform delicate tasks.”

Dickey is conducting his research under an NSF Faculty Early Career Development (CAREER) award, which he received in 2010.

Before the experiments with the Gallium/Indium alloy, the NCSU researchers had tried other versions of shape-shifting antennas, but were using mechanical deformation to alter the shape, later shifting to utilizing electricity as primary form factor.