New ‘explosive jumping’ robot features 3D-printed body of gradient stiffness (VIDEO)

Engineers at Harvard University have designed the first 3D-printed, autonomous robot that transitions from a rigid body to a soft one which can jump. Powered by a mix of butane and oxygen, it can jump more than 20 times its own height, yet land upright.

The team of engineers from Harvard University and the University of California San Diego (UCSD) wanted the autonomy and speed of a rigid robot, with the adaptability and resiliency of a soft robot. Using a multi-material 3D printing process, the team combined stiff plastic and squishy rubber in nine layers of printed materials to create the jumping robot.

“This robot is a demonstration of a method to integrate the rigid components with the body of the soft robot through a gradient of material properties, eliminating an abrupt, hard-to-soft transition that is often a failure point [in robotic design],” said Robert J. Wood, Harvard’s Professor of Engineering and Applied Sciences, and senior author of the study, in a statement

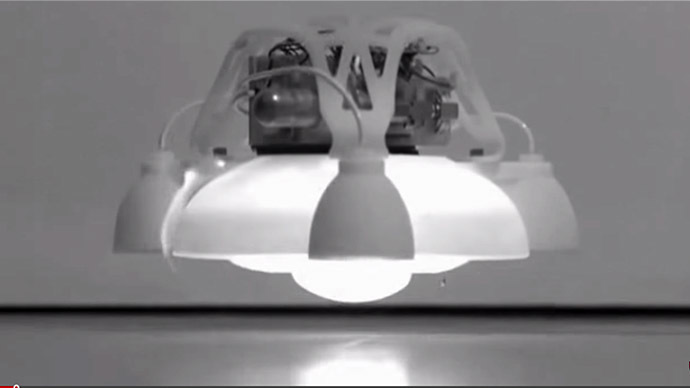

The robot comes with a core body featuring a custom circuit board, a high voltage power source, a battery, an air compressor, butane fuel cells, six valves, an oxygen cartridge, and a pressure regulator and ducts to move the gas around.

To jump, the robot inflates one or more of its pneumatic legs to point the body in the direction it wants to move to, fills the body with a mixture of oxygen and butane, and then ignites itself. This expands the flexible bottom of the robot, propelling it into the air.

The robot can jump more than 20 times and reach more than 2.5 feet (0.75 meters), or six times its own height. It also moves half a foot (0.15 meters) laterally.

Integrating rigid and soft materials has challenged robotic engineers for years.

“[Bringing] together soft and rigid materials will help create a new generation of fast, agile robots that are more robust and adaptable than their predecessors and can safety work side by side with humans,” said Michael Tolley, an assistant professor of mechanical engineer at UCSD, and the paper’s co-lead author, in a statement.

Tolley said the inspiration for blending soft and hard materials came from nature. Certain species of mussels have a foot that starts out soft and then becomes rigid at the point where it makes contact with rocks.

“In nature, complexity has a very low cost,” Tolley said. “Using new manufacturing techniques like 3D printing we’re trying to translate this to robotics.”

Researchers describe the robot’s design, manufacturing and testing in the July issue of Science magazine.