Russian space producer breathes new life into single-stage carbon fiber rocket project

Apparently inspired by the success of Falcon 9, a Russian rocket producer has reportedly revived a project to make a reusable robotic launch system. A rare new engine will be required to complete the innovation, however.

The revival of a project called ‘Korona’ by the Makeev Rocket Design Bureau was reported on Tuesday by Interfax news agency, citing the company’s Chief Designer Vladimir Degtyar.

The rocket was in active development by the Bureau between 1992 and 2012 before ceasing due to a lack of funding for the prototype phase. In January 2017, it was reported that the designer was eager to revive the development. It is unclear whether funding has since been secured.

Korona is one of several historic designs for a reusable, single-stage space carrier; which also include the McDonnell Douglas DC-X system in the US, and Japan’s RVT project. The Russian robotic vehicle, ironically, was not intended to be a reusable rocket, as suggested by its name. The acronym KORONA stands for a phrase in Russian meaning “One-use space rocket, single-stage carrier for spacecraft.” Designers later suggested reusing the expensive rocket in the interest of economic efficiency.

Central to the project is the single-stage-to-orbit approach, which means that no part of the vehicle is jettisoned during the launch. This allows for a more robust structure, while reusing the rocket makes each launch significantly cheaper.

One major drawback of the approach is that such a rocket would require a specialized method of propulsion, since engines used at different stages of a multiple-stage rocket are each designed to work well at a specific altitude range. A range of suggested solutions include an assisted launch from the back of a carrier plane, nuclear or beam propulsion, and the creation of an engine that is effective at all altitudes.

The Makeev designers opted for the latter and say they want a new aerospike engine to be developed for Korona. This type of engine uses a spike-shaped plug instead of a traditional expanding bell-shaped nozzle to direct the engine exhaust. The design has been studied for years and was even considered at one point for the main engine of the Space Shuttle. However, no commercial model is available at present. The Bureau says the rocket would use liquid hydrogen and oxygen for propellant and oxidizer.

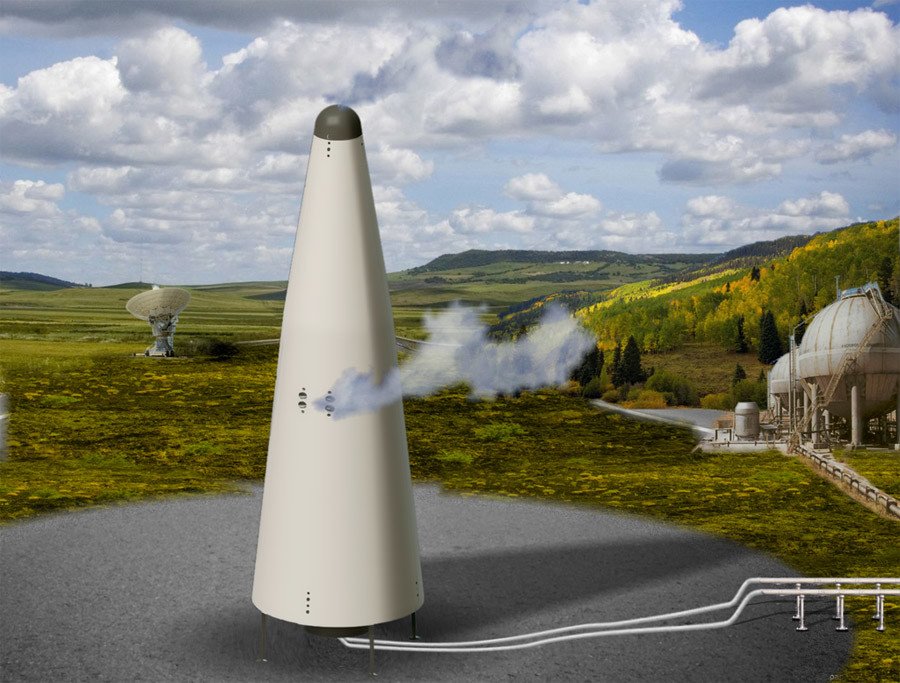

The Korona rocket will also be made viable through the use of carbon-fiber-reinforced materials in its structure. These are lighter than metals and allow for a larger payload to be boosted into orbit with the same structure and engine. Its sharp, conical shape is also intended to increase the mass ratio – a smaller nose means that fewer heavy ceramic heat-shield plates are required to protect the rocket during launch and atmosphere re-entry.

The latest design estimates that the final rocket would weigh less than 300 tons and deliver six to seven tons of cargo into low Earth orbit, or even more if orbital refueling is possible for the return flight.

Its reusability would be achieved by incorporating vertical landing, similar to how the first stage of Falcon 9 is rescued after launch. This will probably be a more complex problem, considering that Korona is not expected to be used for suborbital flight, and will instead be returning from space.