3D printer produces synthetic ‘tissue’ (PHOTOS)

Researches have built a new type of 3D printer that creates tissue-like material that could revolutionize medicine. The artificial material produces the properties of living tissues and could potentially replace them in the future.

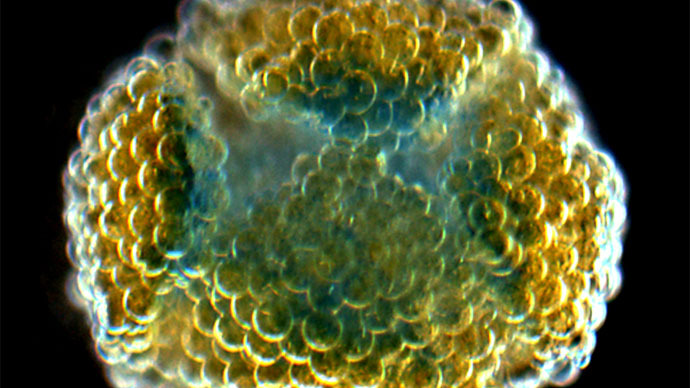

The new material developed by scientists at Oxford University consists of water, coated and protected by lipid molecules. The tens of thousands of 3D connected caviar-like droplets were named 'droplet networks'.

“We add chemicals and bio chemicals. This changes the water.

After all we humans are made of networks of water droplets”

Professor Hagan Bayley of Oxford University's Department of

Chemistry commented, as cited by the Daily Mail.

The'droplet networks' could one day replace damaged living tissue or deliver drugs to specific locations, the researchers said in a study released Friday in Science magazine.

"We aren't trying to make materials that faithfully resemble tissues but rather structures that can carry out the functions of tissues," said Professor Bayley in a news briefing on the Oxford university website.

"The droplets can be printed with protein pores to form

pathways through the network that mimic nerves and are able to

transmit electrical signals from one side of a network to the

other," he added.

Eventually this material could replace the use of stem cells, a completely synthetic material, has no genome and does not replicate. The creation of 'droplet networks' avoids many problems such as harvesting living tissue.

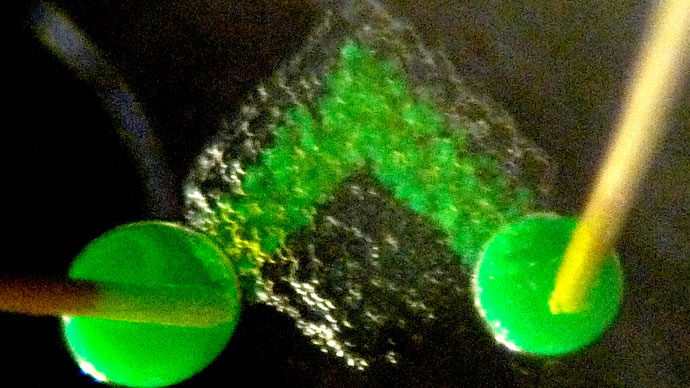

The Oxford scientists said that there was no printer to build these aqueous droplets as so far they have developed 3D printers that can only create solid objects. So they found a way out by building one in their laboratory. The unique 3D printer was built by Gabriel Villar, a student and the lead author of the paper.

"Conventional 3D printers aren't up to the job of creating these droplet networks, so we custom built one in our Oxford lab to do it," said Professor Bayley.

Each droplet is 50 microns in diameter, about 0.05 millimeters,

but it is five times larger than a living cell. Professor Bayley

said that given more time and funding they will be able to develop

smaller networks.

"At the moment we've created networks of up to 35,000 droplets but the size of network we can make is really only limited by time and money. For our experiments we used two different types of droplet, but there's no reason why you couldn't use 50 or more different kinds."

At present the material remains stable for weeks.

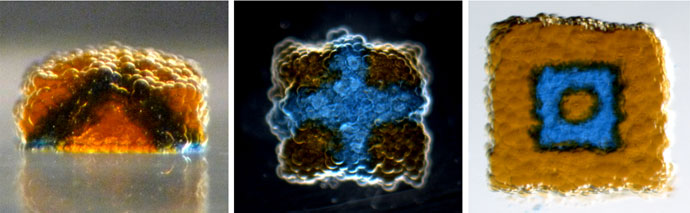

This synthetic material can be designed to take on different shapes after it was printed. This resembles muscle movement.

The researchers have demonstrated the through the creation of a flowerlike droplet network that from the initial flat shape curls into a sphere.

The movement is triggered by a process called osmosis.

The droplets on the bottom of the network are filled with

a high concentrated solution, and the ones on the top are filled

with a low concentration. After the droplets are printed the

solvent molecules on top flow into the droplets on the bottom

through a partially permeable membrane. When that happens the

droplets on top shrink and the droplets on the bottom blow up

causing the whole structure to curl.

3D printing gives vast opportunities such as to create objects as complex as human organs. There are certain advantages of using artificial tissue in comparison with living tissue, says Cameron Ferris a research associate from the ARC Centre of Excellence for Electromaterials Science at the University of Wollongong, ABC Science reports. He is part of a team that develops 3D printers to potentially create replacement organs using living cells.

"It's incredibly expensive to harvest stem cells [for 3D printing of living tissue], and the food you have to feed them, to grow and expand them so that you have enough stem cells to print takes some time” he said, according to ABC science.