The British Royal Air Force’s Tornado fighter jets have performed their first flights with some onboard metal parts manufactured using revolutionary 3D printing technology, defense firm BAE Systems has announced.

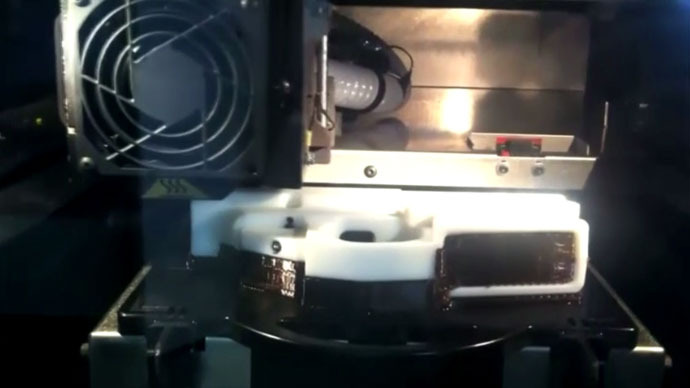

The firm’s 3D engineers designed several parts, among which is a cockpit radio cover and guards for power take-off shafts. This could pave the way for an estimated 1.2 billion pounds in savings on the RAF’s maintenance bill, the Press Association revealed Monday.

The aircraft flew from the manufacturer’s airfield in Warton, Lancashire, in December.

Some parts currently being produced for four squadrons of the Tornado GR4 jets are as cheap as 100 pounds, with the added benefit of being able to manufacture them at any convenient location.

“You are suddenly not fixed in terms of where you have to manufacture these things.,” said Mike Murray, head of airframe integration at BAE Systems. “You can manufacture the products at whatever base you want, providing you can get a machine there, which means you can also start to support other platforms such as ships and aircraft carriers… And if it's feasible to get machines out on the front line, it also gives improved capability where we wouldn't traditionally have any manufacturing support."

3D printing is a new, relatively cheap technology that promises to revolutionize many industries and endeavors by making exact copies of objects out of any material, fast. 3D printing has already made a big splash in medicine and is now moving into the military – a prospect both exciting and scary to some.

3D-printing uses cutting-edge technology that costs less money than traditional production, and is quickly developing, being applied in many spheres.

Last August, NASA published a video that demonstrated a rocket engine partly manufactured using 3D-printing technology. If mass production starts, it could slash costs by 70 percent.

In November, engineers in Texas made a fully functioning metal gun, using a 3D printer loaded with powdered metals.

And researchers from the University of Louisville have already pledged to make replicas of a human heart within a decade.